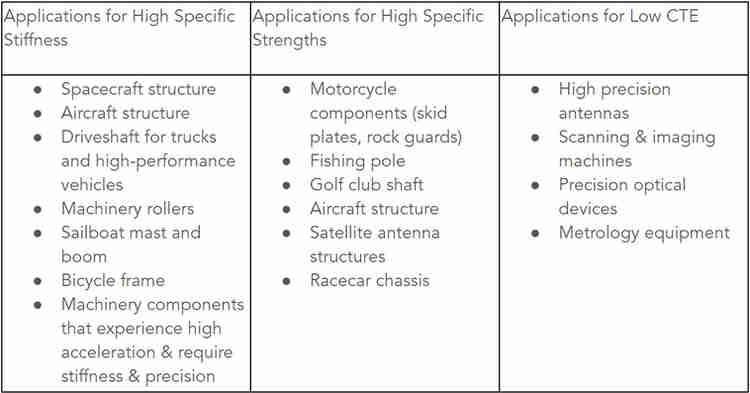

The unique positioning of the carbon fiber composites with high specific strength, stiffness, and low CTE provides them a unique place in many application areas as shown in the table below:

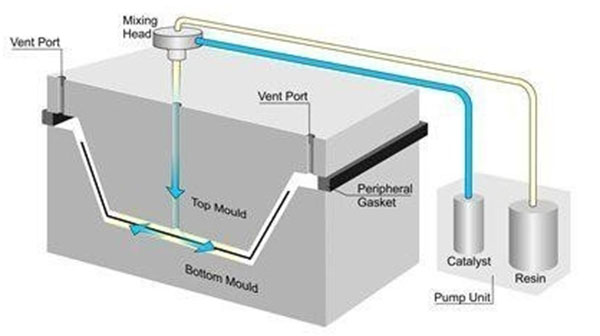

The unique positioning of the carbon fiber composites with high specific strength, stiffness, and low CTE provides them a unique place in many application areas as shown in the table below: Molds are used to define the shape of the composite parts. The composite part will pick up all shapes and features of the molds; therefore, the quality of the domain is heavily influenced by the quality of the mold. The molds can be either male or female. The female molds are the most common, producing a part with a smooth exterior surface, while a male mold will have a smooth interior surface. A matched mold (male and female) is required if the part is consolidated using a press.

Molds are used to define the shape of the composite parts. The composite part will pick up all shapes and features of the molds; therefore, the quality of the domain is heavily influenced by the quality of the mold. The molds can be either male or female. The female molds are the most common, producing a part with a smooth exterior surface, while a male mold will have a smooth interior surface. A matched mold (male and female) is required if the part is consolidated using a press.